Bin Location Create

📦 E-Learning Content Module: Bin Location (Inventory Management)

Module Title

Bin Location System in Inventory Management

Learning Objectives

By the end of this module, learners will be able to:

Understand the concept of a Bin Location System.

Identify the importance of bin locations in warehouse operations.

Explain how to set up and label bin locations.

Demonstrate how to use bin locations to improve stock accuracy.

Apply best practices for maintaining bin locations.

Content Outline

1. Introduction to Bin Location System

Definition of Bin Location

Purpose of bin locations in warehouses

Difference between Fixed vs Random Bin Location systems

2. Importance of Bin Location

Improves picking efficiency

Reduces errors in stock handling

Saves time in locating items

Enhances stock accuracy during cycle counting

3. Bin Location Coding and Structure

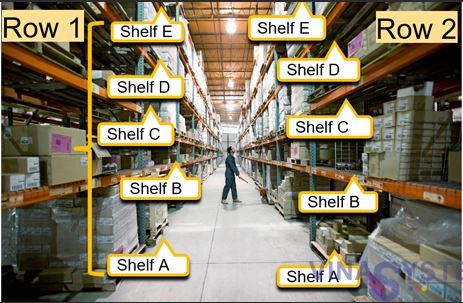

Common coding methods (e.g., Aisle-Row-Shelf-Bin)

Example: A01-R02-S03-B05 = Aisle 01, Row 02, Shelf 03, Bin 05

Benefits of a structured coding system

4. Setting up Bin Locations

Warehouse layout planning

Labeling techniques (barcodes, QR codes, RFID tags)

Safety and accessibility considerations

5. Using Bin Locations in Daily Operations

Receiving & put-away process using bin codes

Picking and packing with bin locations

Stock transfers within bin locations

6. Best Practices

Regular bin audits and cycle counts

Keep bins neat and accessible

Ensure bin codes are visible and consistent

Update system immediately after stock movement

7. Common Challenges & Solutions

Misplaced items → Regular cycle counts

Missing bin labels → Re-labeling process

Overcrowded bins → Apply maximum bin capacity rules

Reading Material (2 Pages)

Page 1: Introduction, Importance, Coding System

Page 2: Setup, Operations, Best Practices, Challenges

Suggested YouTube Link

👉 Warehouse Bin Location Explained

FAQs (10)

Q: What is a bin location?

A: It is the specific storage spot in a warehouse where inventory is kept.Q: Why do warehouses use bin locations?

A: To improve accuracy, speed, and organization in inventory management.Q: What is the difference between fixed and random bin locations?

A: Fixed bins store the same item in the same spot, while random bins can store different items depending on availability.Q: How are bin codes created?

A: Using warehouse structure like aisle, row, shelf, and bin numbers.Q: Can barcodes be used for bin locations?

A: Yes, barcodes or QR codes make bin tracking faster and more accurate.Q: What happens if an item is placed in the wrong bin?

A: It may cause picking errors; regular cycle counts help detect and correct this.Q: How do bin locations help in picking?

A: Workers can go directly to the correct bin instead of searching the warehouse.Q: Should bin locations have capacity limits?

A: Yes, to avoid overcrowding and damage to items.Q: Who is responsible for maintaining bin locations?

A: Warehouse staff under the supervision of the warehouse manager.Q: How often should bin audits be done?

A: At least monthly or according to company policy.

| Responsible | 7l-Khine Mar Wai |

|---|---|

| Last Update | 2025 စက် 28 တနင်္ဂနွေ |

| Completion Time | 4 မိနစ် |

| Members | 23 |

-

-

Preview

-

Preview 10 xp

-